Kawasaki 99916-2164 John Deere AM132715 Fuel Pump Diaphragm failure dissection

We had an older John Deere tractor in the shop recently with what could only be described as a major fuel leak when running. Idling the tractor in a fixed location resulted in a pool of fuel forming underneath in a short time. Shutting off the tractor stopped the leak so clearly this fuel was being pushed out under pressure.

Tracing the leak was pretty easy. It was coming from the fuel pump diaphragm vent hole. As the engine idled, you could see a spray of fuel being spit out by the fuel pump on every engine cycle.

We hate working on fuel system problems because of the danger, the smell and the cleanup after, but this looked to be straightforward repair if we could get a drop in part. Some internet research told us this John Deere used a Kawasaki motor that was common in multiple power machines like Cadet and MDT.

We called in a parts order to our local dealer and it look 20 minutes to drop in the fuel pump. Once it got primed the tractor was on it way.

What caused the failure? We carefully filled the pump with water and cycled the pump a few times over several days drying it in the sun in between to rid it of fuel. Then we took it outside and cut it open:

Internal Construction

Top View showing pump chamber

Top View showing diaphragm

The failure was obvious – the rubber diaphragm had multiple cracks:

Diaphragm cracks

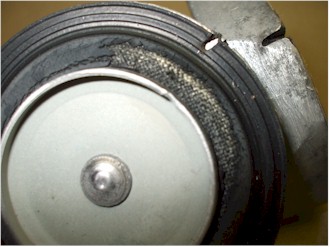

One edge of the diaphragm has a break through zone which allowed the fuel to leak through on every cycle:

Diaphragm break through zone

While colleagues advised me that this is being seen routinely now because of the chemical make up of fuel today slowly dissolves the diaphragm material.

If you have such a fuel pump, be sure to connect the weep hose to ensure fuel is directed away from the muffler!